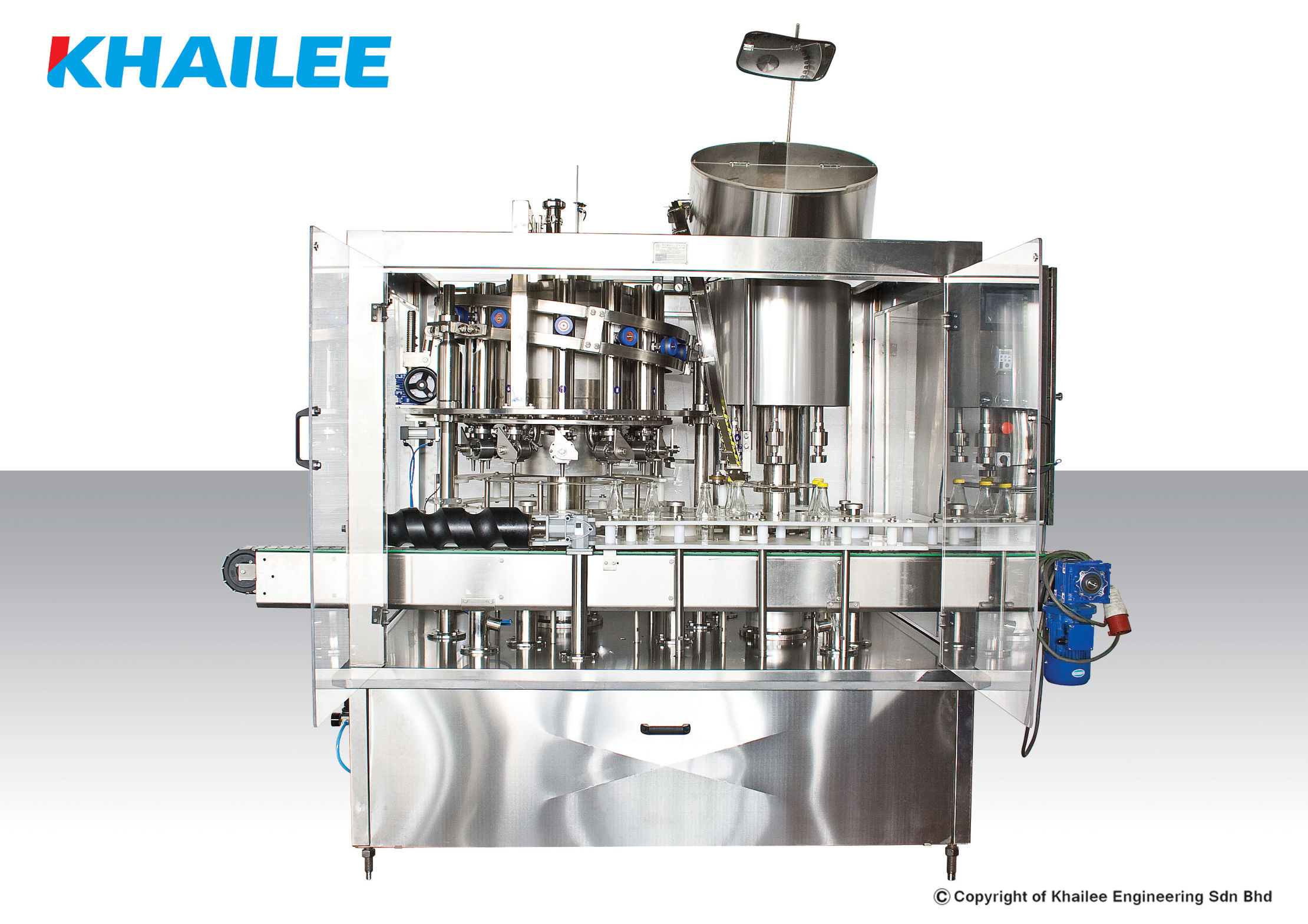

Rotary Piston Filling and Capping Machine is a compact modular bottle handling system, which - combined rotary piston filler with rotary capper as a monobloc –automatically fills and automatically applies caps to bottles whereby the caps could be elevated by an optional unit of automatic cap elevator. The assortments of products that piston fillers can accommodate is almost unlimited, ranging from water thin liquid to thick creams and pastes, catering food, pharmaceutical, cosmetic, chemical and numbers of other specialty industries

The machine incorporates variable speed electrical gear motor drive. The rotational drive turns a rotatable cam that drives the volumetric piston rod to perform the filling operation. As a monobloc machine, the machine served combines the filling station and capping station as one. Therefore, the bottling process is aligned and reasonable high speed. The volumetric piston filler capable of accurately and efficiently filling a wide variety of products ranging from semi-vicious to viscous product. Filling station consists of filling head and a rotary turret with possible up to 24 nozzles.