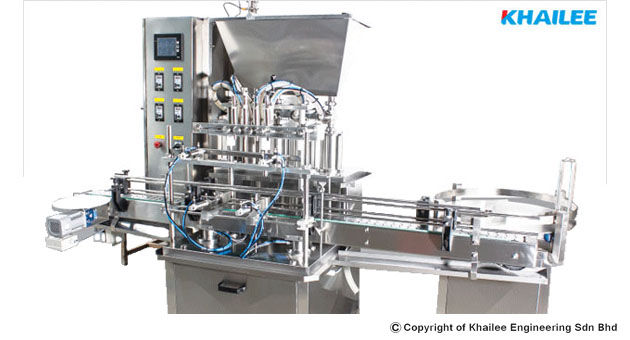

It is used to fill from medium to high viscosity products and capable of handling product with particles. The volumetric filling machine can be controlled by either pneumatic cylinder or servo motor. We’re using Individual Volume Control by using 1 To 1 Mechanism whereby each piston chamber comes with its own pneumatic cylinder in order to provide individual volumetric adjustment, and hence ensuring better filling accuracy.

In addition, the new improved volumetric filling machine is now controlled by Servo motor; it provides the ease and flexibility of simple touch screen for setting product volume and more accurate filling volume.