The Automatic Gravity Filler is ideal for filling thin liquids with consistent viscosity. Gravity filling method produces repeatable and accurate fill volumes. The Gravity Filler is manufactured with a heavy duty 304 stainless steel, tig-welded tube frame and reservoir. It also features user-friendly PLC controls and touch screen HMI panel.

Gravity Fillers are utilized by the food and beverage, cleaning and specialty chemical, pharmaceutical, cosmetic, and personal care industries for various filling projects.

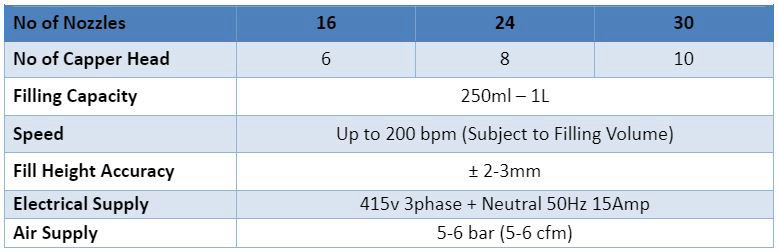

This machine fills to a target fill height in the container rather than volumetrically. As long as the container specification does not vary significantly, the volumetric accuracy of this machine is excellent. The machine incorporates variable speed electrical gear motor drive. As a Monoblock machine, the machine served combines the filling station and capping station as one, therefore running at a reasonable high speed with excellent filling accuracy.